Some additional thoughts and perspective on reference marks and layout from reader Willard “Bill” Anderson and myself.

When working by hand, minor inconsistencies in thickness or parallelism between faces or edges can cause major problems with joinery if the reference face and edge are ignored.

In today’s video I’ll show you how to camber a plane iron without a grinder.

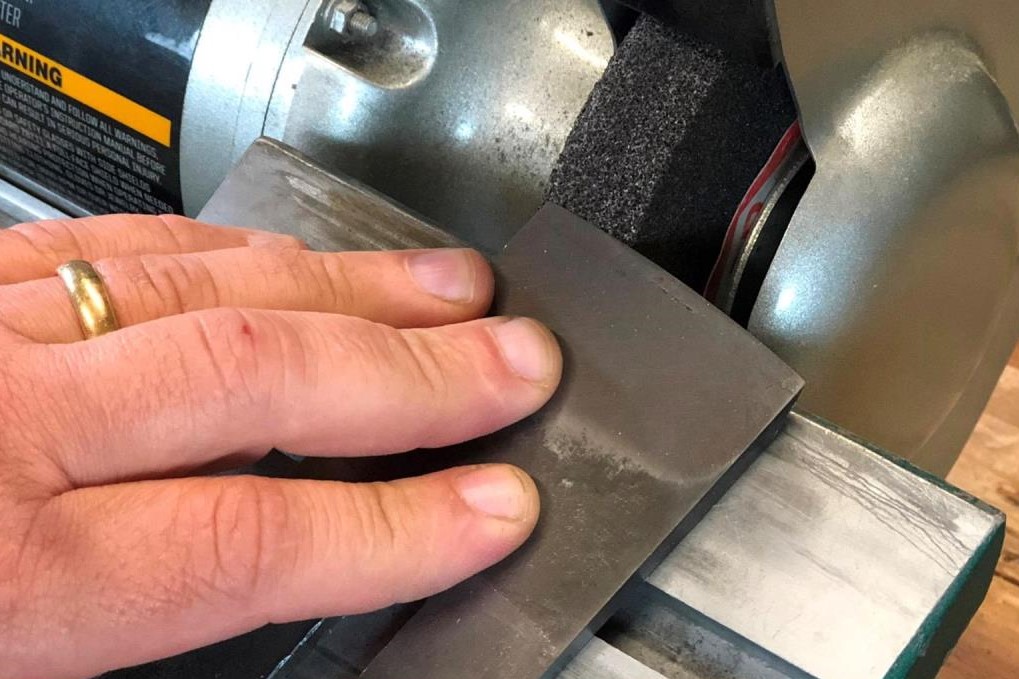

In this video, I demonstrate using a high speed grinder to camber the cutting edge of a jack plane blade.

In this video I’m making a simple waist molding that serves to draw the eye upwards from the floor and transition from a lower case to an upper case.

I just finished building a Welsh style stick chair, but when assembling the arm and spindles to the seat, a small crack opened up in the arm. Here’s a cool trick for repairing these small cracks when a glue brush or syringe won’t fit.

It’s inevitable. No matter how careful you are fitting your joinery, doing dry assemblies to check fit, and rehearsing your assembly process to make sure you have everything in place and ready to go, Murphy is going to show up from time to time and throw a little hiccup into things.

If you’ve been around woodworking hand tools for a while, you’ve likely heard of the hand saw hack that lets you saw perfectly square across a board without the aid of a pencil line to guide your cut. Wait! You haven’t seen this before? Here, hold my beer.

Try these three tips to improve your hand sawing.

While sawing precisely by hand may seem like black magic when you’re first learning, the secret to precision hand sawing, if you can call it that, is starting the cut precisely, and proper body mechanics during the cut.

In this video, I demonstrate an exercise I call “saw without sawing”. This short exercise helps to teach the new hand saw user what it feels like to take the weight of the saw off of the wood when starting a cut with a hand saw, and makes for more precise cuts.

A common struggle for new hand saw users is starting the saw cut cleanly and accurately. While the symptoms being experienced might seem like a problem with the saw itself, they are all caused by improper technique.