The problem with most recommendations for the best first hand plane to buy is that they don’t take into consideration the individual’s staring point.

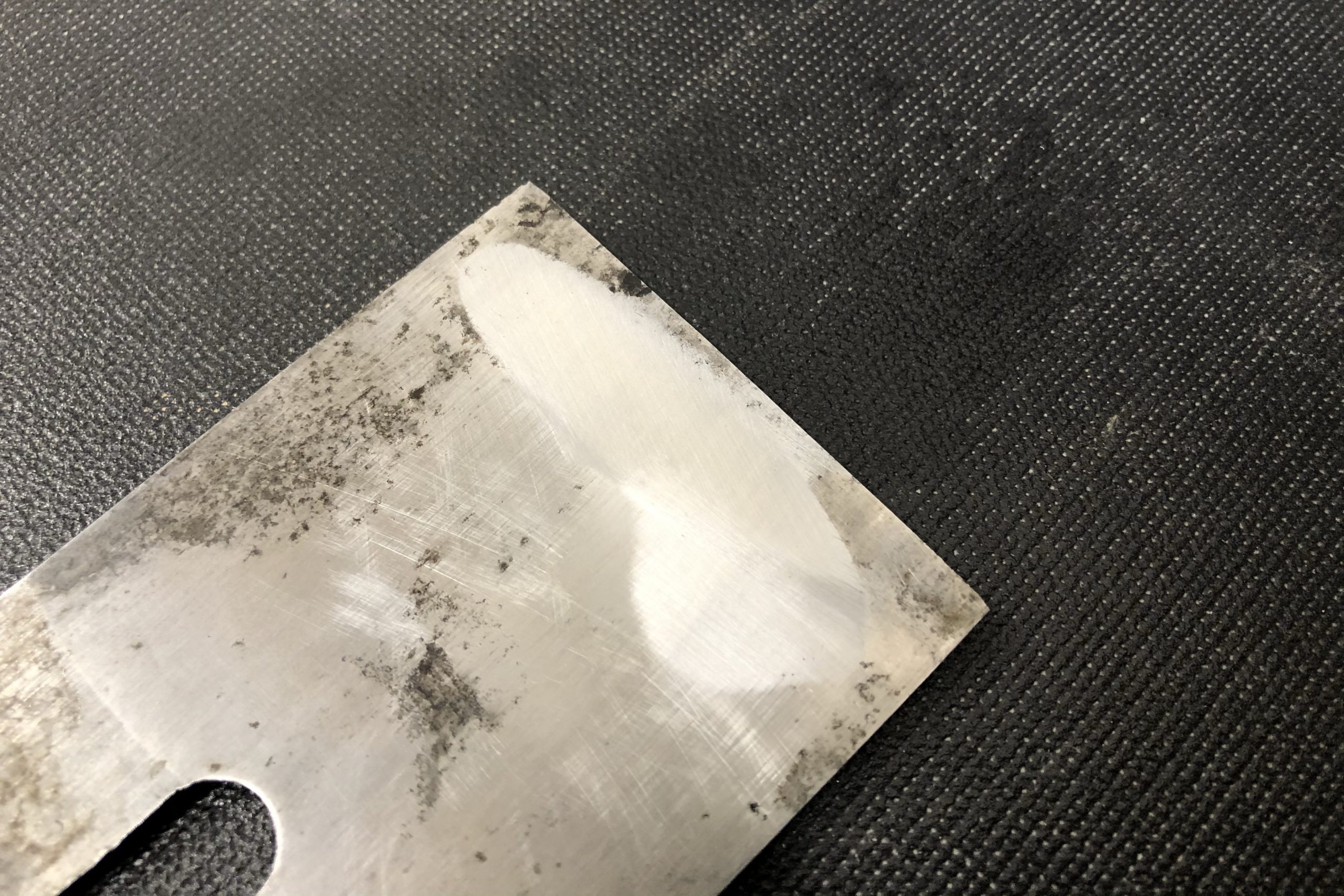

Grinding and honing a router plane blade can be a challenge, as it’s a freehand operation. A hollow grind is a huge aid in freehand honing.

I started writing this yesterday, and it ended up entirely too long for a single post. So today is the second half of my novella on storing hand tools.

I’ve been woodworking now for over 30 years. In that time, I’ve tried just about every solution you can imagine for storing hand tools.

A quality combination square usually comes with a steel scriber. However, sometimes the bushing that’s supposed to hold the scriber in the handle, doesn’t.

I know that not everyone that gets one of these planes will get the manual with it, so I’ve created a high resolution scan of the manual that came with my plane. Feel free to download and print it for your own use.

Throughout my series of posts on milling lumber by hand, I used several different hand planes. Each of the planes that I used was chosen for the specific tasks that they excel at. The jack plane is the perfect size …

A few posts ago I talked about dealing with a badly warped blade from a wooden bodied hand plane, and then addressing issues with the bed of a wooden plane. These posts might suggest that wooden bodied hand planes are not as reliable or as functional as their iron siblings and that they’re not worth the effort to bother trying to use. However, nothing could be further from the truth.

Sometimes, tuning up a wooden hand plane requires a little more than sharpening the blade and flattening the sole.

WARNING: If you are a sharpening purist or a flat back Nazi, stop reading this right now, go to your safe place, and watch a few cat videos. If you ignore this advice, understand that what you are about to read is guaranteed to trigger you in ways that you’ve never imagined. Continue at your own risk.

I use card scrapers a lot in my work. They’re not only extremely valuable for smoothing areas of difficult long grain, I also use them all the time for cleaning up and smoothing end grain as well. However, for a …

Just about everyone who has ever used a hand saw has bent or kinked a saw in use at some point. Sometimes the bend springs back, and sometimes it doesn’t. However, bending a saw doesn’t necessarily relegate it to becoming scraper stock or wall art. In many, if not most cases, the saw can probably be straightened out again.