Making Kitchen Cabinets – Choices in Drawer Slides

Note: Click here for all the posts in this build series.

When I last left the kitchen cabinet project, I had completed the build of the cabinet box by making and attaching the face frame. With the box done, the next thing that I typically tackle are the drawers and pull-out shelves. It’s usually easier to access the inside of the cabinet for installing pull-out shelves without the doors in place, so rather than remove the door later, I’ll take care of the shelf now.

However, before building the drawer(s) for any cabinet that will utilize mechanical drawer slides, it’s absolutely critical to have the hardware on hand. In a traditional case piece, the drawer just needs to fit the opening. When mechanical slides are used, the space required for the slides to operate must be accounted for, so the drawer box can’t just be made to the size of the opening. Careful measurement has to be made to make sure that the proper clearance for the slides being used is included. Too little or too much clearance and the drawer either won’t fit the opening, or won’t operate correctly.

So before building the drawer and pull out shelf, let’s take a brief look at some options for drawer slides.

Three-Quarter Extension Roller Slides

The most inexpensive style of slide is the side mounted, or bottom mounted, three-quarter extension roller slide. These slides are very inexpensive, usually less than $10 for a pair of slides for a 24″ deep cabinet. They’re most often found in inexpensive, in-stock kitchen and bath cabinets at home centers, and cabinets in most kitchens in the US built before 1980.

These slides are relatively easy and forgiving to install. One piece attaches to the side or bottom corner of the drawer and the other half attaches to the inside of the cabinet face frame (for cabinets with face frames) or box (for frameless cabinets). The clearance required on the sides and bottom of the drawer varies depending on the style (side or bottom mount) and manufacturer of the slide, so it’s important to measure the thickness of the assembled slide BEFORE building the drawer box.

I always add an extra 1/32″ or so of clearance when using these slides because they have quite a bit of slop in the mechanism to account for a slightly narrower drawer. On the other hand, if the drawer is much too narrow, it will tend to jump the track in use, which is no good at all. At the same time, these slides will not be tolerant of a drawer that is slightly too wide. Another down side to these slides is that they generally cannot support much weight. I personally wouldn’t use them to hold a shelf full of dishes or cast iron cookware.

In frameless cabinets, these slides simply screw to the side of the cabinet box along their entire length. However, in cabinets with face frames, the slides are mounted to the inside of the face frame. As a result, the end of the slide at the back of the cabinet has nothing to attach to. One option for solving this problem is to build out the side of the cabinet flush with the face frame by using a block of wood. Alternatively, the slides can be hung from the back of the cabinet using a purpose made mounting bracket. These are especially useful when drawers are not mounted close enough to the cabinet sides to allow the use of blocking.

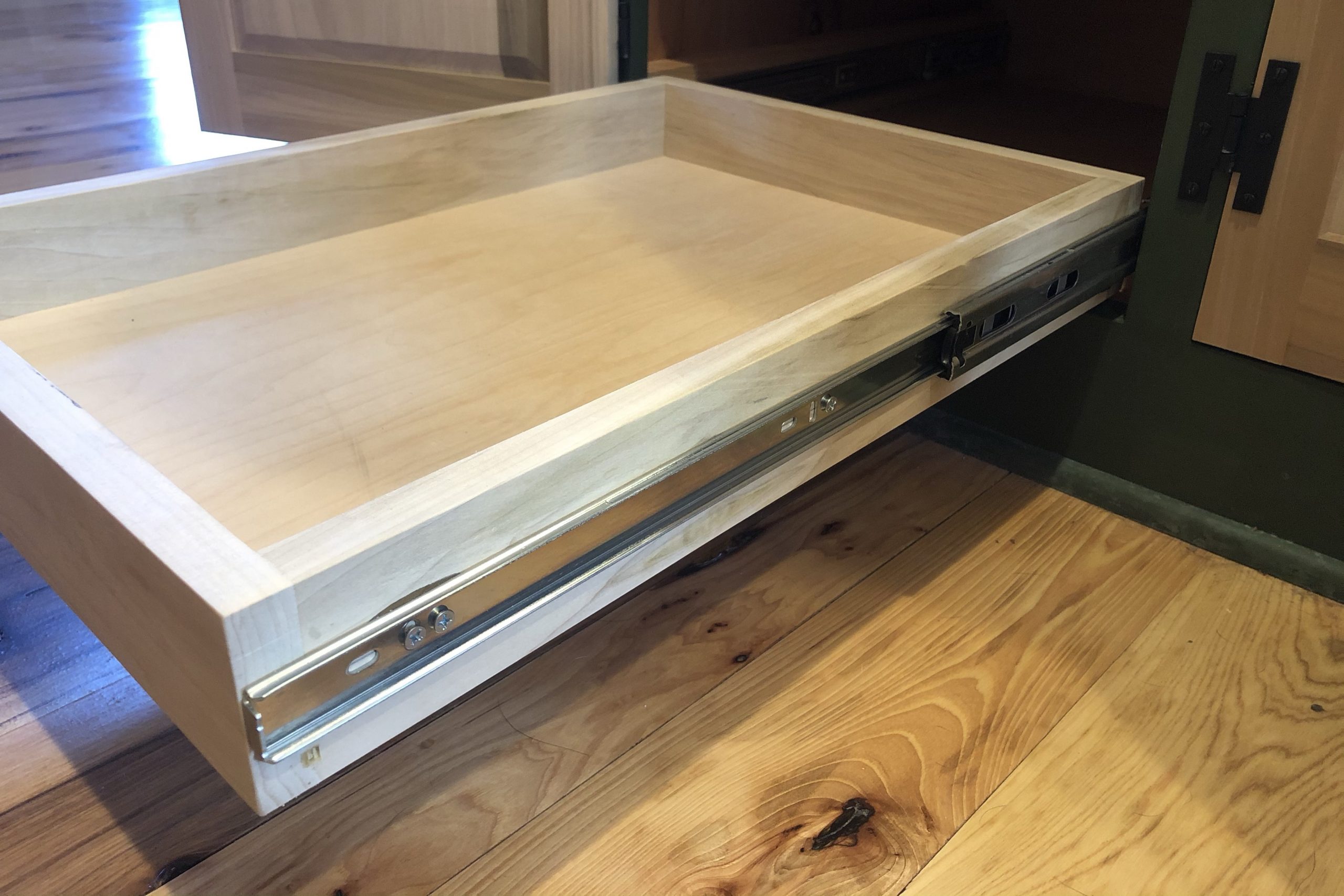

Side-Mount Full Extension Ball Bearing Slides

One of the easiest types of mechanical slides to use are side-mounted, full extension ball bearing slides. These slides are a bit more expensive at about $20 or so per set. They are almost universally 1/2″ thick and are designed to mount to the side of the cabinet box, but can also be hung with brackets when used in a cabinet with a face frame. However, my favorite way to hang these in face frame cabinets is just to block out the side of the cabinet since the slides are so big anyway.

Since they are mounted on the side of the drawer, it’s easy to figure the drawer size. All that’s required is to make the drawer box 1″ narrower than the drawer opening. I like to use these types of slides for pull out shelves because they are heavy duty but less expensive than hidden undermount ball bearing slides. They can support a lot of weight, and being full extension, getting things at the back of the shelf is really easy. I don’t care to use these on drawers, however, as they are kind of ugly.

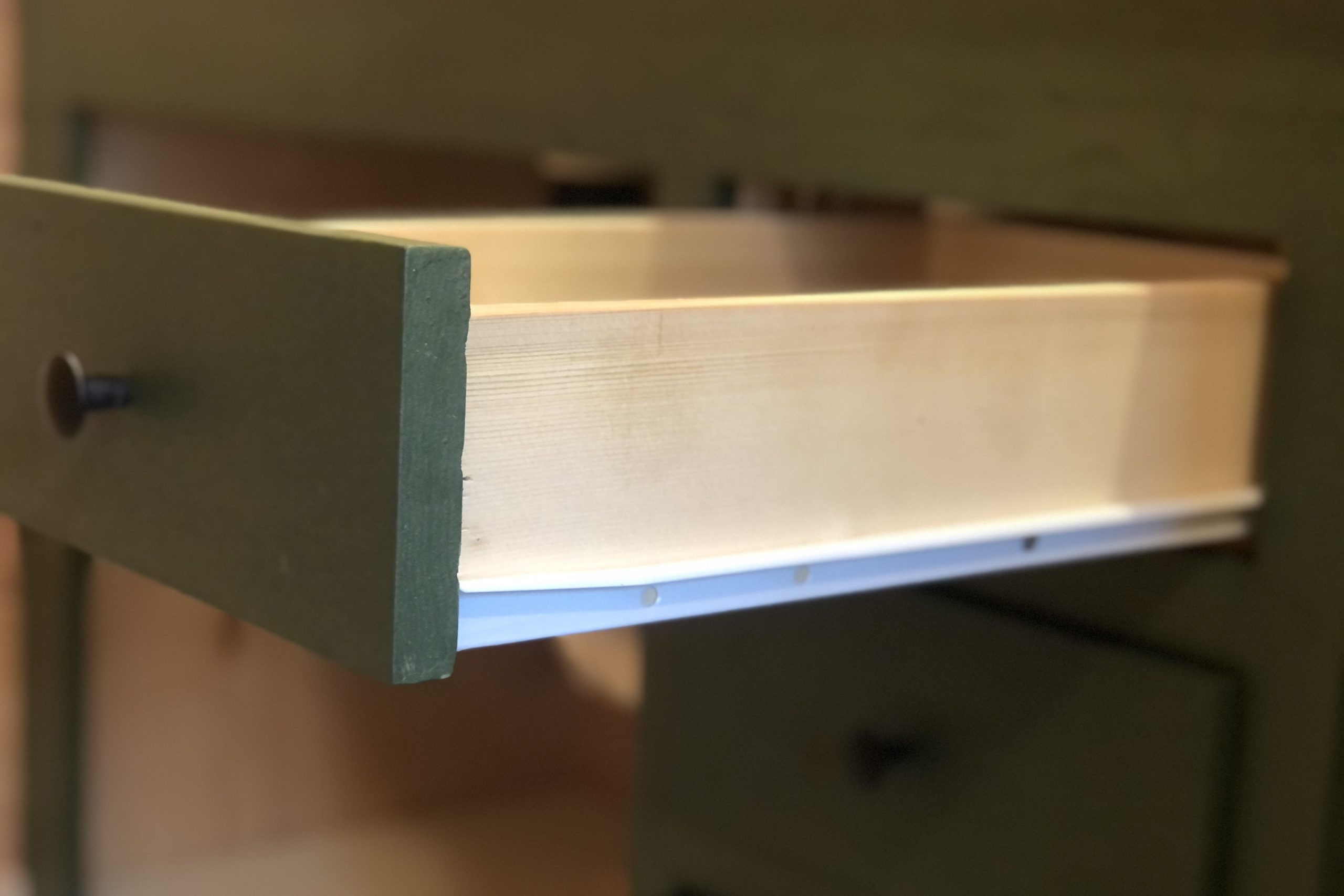

Undermount Full Extension Ball Bearing Slides

These are the most expensive of the available mechanical drawer slides, typically costing $35 or more per set. However, the design of these slides allows them to be virtually unseen once the drawer is installed. They can be used for pull out shelves as well, but in those situations, the slide isn’t really going to be hidden like it will be in the case of a drawer box, unless the sides of the pull out shelf are very tall, like a drawer. Even then, you’ll still see them when you pull the shelf out, so I find the added cost of undermount slides over side mount slides provides no real benefit when it comes to pull out shelves.

Having the slides hidden in use not only costs more in the wallet, it costs more in time as well. Installing undermount slides is much more persnickety than installing side mounted slides. First, the drawer box has to be built to very particular dimensions in order to fit the slides. Second, the slides have to be installed very precisely in order for them to work properly. Finally, unless you spend even more money on special adjustable drawer attachment clips, the adjustability of undermount slides is very limited and can try even the most tolerant person’s patience.

Still, the end result is worth it to most people. When installed and adjusted properly, undermount slides practically disappear from sight. They also operate very smoothly and quietly, they can support a lot of weight, and drawers are extremely easy to install and remove once the hardware is mounted.

Center-Mount Slides

The center mount slide is a single slide that, as its name implies, mounts to the center bottom of the drawer. These slides come in many different configurations. There are simple roller versions like the three-quarter extension roller slides discussed above. There are ball bearing versions similar to the full extension side mount slides discussed above. There are versions that use a steel track with a wooden or plastic guide that attaches to the drawer box. There are even versions made completely of wood.

Like the undermount slides just discussed, this type of slide is hidden in use, but don’t mistake these for a less expensive version of undermount ball bearing slides. Honestly, in my opinion, center mount slides are really not even worth considering if you are going through the effort to build your own cabinets. If you have ever purchased a cheap piece of furniture you are likely already familiar with center mount slides and how useless they are. Because there is only a single center slide, the drawer can’t support much weight. Also, if the drawer is more than just a few inches wide, it will rock side to side on that single center slide, until the torque causes the slide or the guide to break, making the entire thing useless. I personally can’t think of any circumstance where one of the previous three versions wouldn’t be an infinitely better option than a center mount slide.

My Drawer Slide Preferences

As noted above, when it makes sense for me to use mechanical drawer hardware, I really like undermount ball bearing slides for drawers. I like that the slide is hidden from view when the drawer is open, I like the weight that they can support, and I like how smoothly and quietly they operate.

When it comes to pull out shelves behind cabinet doors, in my mind the side mount ball bearing slides make the most sense. They can support a lot of weight .They operate smoothly and almost as quietly as the undermount slides. They also cost about half as much as undermount slides. Since the slides are going to be visible when the shelves are pulled out regardless of whether side mount or undermount slides are used, I see no reason to spend the extra money on undermount slides for this application.

As for the three-quarter extension roller slides, I use these when I want a reliable but very inexpensive set of drawer slides. Bathroom vanities are the ideal application for these slides. Usually, bathroom drawers don’t need to hold a lot of weight. Bathroom drawers also don’t typically see the amount of use that kitchen drawers do. I also don’t personally find the need for full extension as critical in a bathroom drawer as in a kitchen drawer. So bathrooms is where I’ll typically use these types of slides.

So, now that I have the slides chosen, I can build the drawer and shelf for this cabinet.

2 Comments

I think you’re right on with your assessment of the different drawer slide types. I used the hidden and side-mounted ball bearing slides when I made our kitchen cabinets. After 10 years, however, the mechanism that pulls the drawer or shelf closed (the last 2 inches) tend to fail on our most-used drawers (like the silverware drawer). The parts that fail are plastic (of course). Given that the average house is sold every 10 years, there may not be a drawer slide that will last for 20 years! LOL

These days, I’d be surprised to see an entire kitchen that would last more than 10 years. Between cheap cabinets & hardware, crap appliances, and HGTV encouraging everyone to remodel every 5 years, kitchens will never last like they used to. My mom still has the refrigerator that my parents bought almost 40 years ago, and it’s never needed a repair. I’d like to see an appliance built today last even half that long.