If you have a power jointer, and flatten board faces on it, you might think that knowing how to do this task by hand is useless, antiquated knowledge. However, there are several reasons why I recommend you learn this valuable skill.

A few posts ago I talked about dealing with a badly warped blade from a wooden bodied hand plane, and then addressing issues with the bed of a wooden plane. These posts might suggest that wooden bodied hand planes are not as reliable or as functional as their iron siblings and that they’re not worth the effort to bother trying to use. However, nothing could be further from the truth.

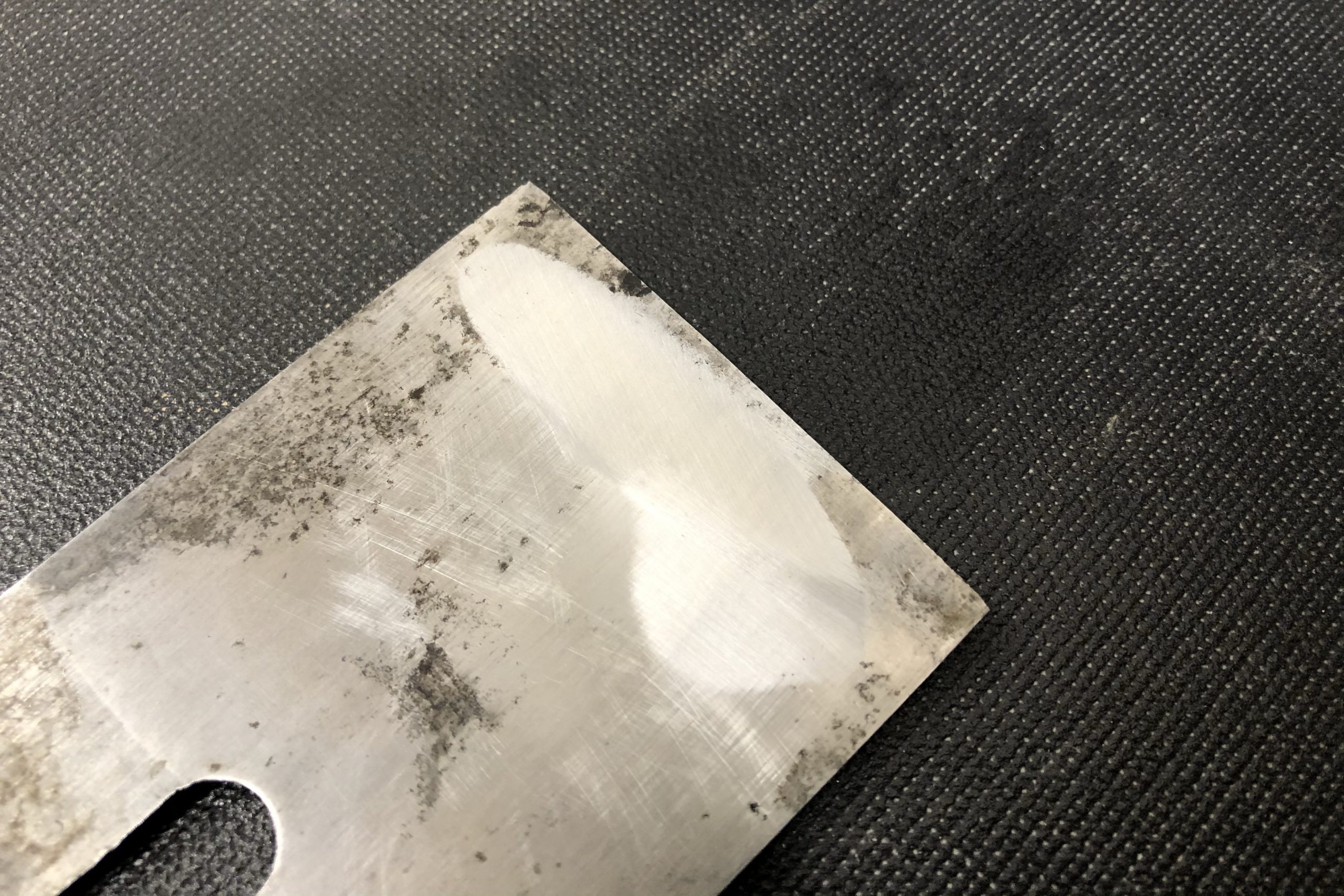

Sometimes, tuning up a wooden hand plane requires a little more than sharpening the blade and flattening the sole.

WARNING: If you are a sharpening purist or a flat back Nazi, stop reading this right now, go to your safe place, and watch a few cat videos. If you ignore this advice, understand that what you are about to read is guaranteed to trigger you in ways that you’ve never imagined. Continue at your own risk.

Applying finish to the parts of a project before assembly of the piece solves some problems that can occur when finish is applied after assembly.

Match planing is a method whereby two boards are placed face-to-face and their mating edges are planed simultaneously. If you aren’t familiar with the technique, allow me to present you with a crash course.

I use card scrapers a lot in my work. They’re not only extremely valuable for smoothing areas of difficult long grain, I also use them all the time for cleaning up and smoothing end grain as well. However, for a …

Just about everyone who has ever used a hand saw has bent or kinked a saw in use at some point. Sometimes the bend springs back, and sometimes it doesn’t. However, bending a saw doesn’t necessarily relegate it to becoming scraper stock or wall art. In many, if not most cases, the saw can probably be straightened out again.

Milk paint is an easy finish to apply, and gives pieces a beautiful and lively color with lots of character. Here’s my method for mixing and applying it.

In the power tool world they’re called jigs. In the hand tool world, we call them appliances.

My shop is much different today than it was when I started making videos over 12 years ago. So today, I give you my shop tour from 2009, and some storage and organization ideas that I used back when I worked out of a much smaller space.

Wooden hand planes can be confusing to the new hand tool user because it isn’t very intuitive how to use them. In this video, I attempt to demystify the process.